This types of hammers has a face pan the one end and a pan is made at the right angle of the handle which is in the taper. Another technique for increasing the width thickness of a piece is upsetting but its generally pretty hard to execute unless you use a torch and control your heat well.

One Single Line Drawing Of Hammer Steel Wooden Hammer Isolated On A White Background Handyman Tools Concept Retro Design Continuous Line Draw Vector Design Illustration Stock Vector Adobe Stock

First heat your stock to a nice bright orangeyellow heat.

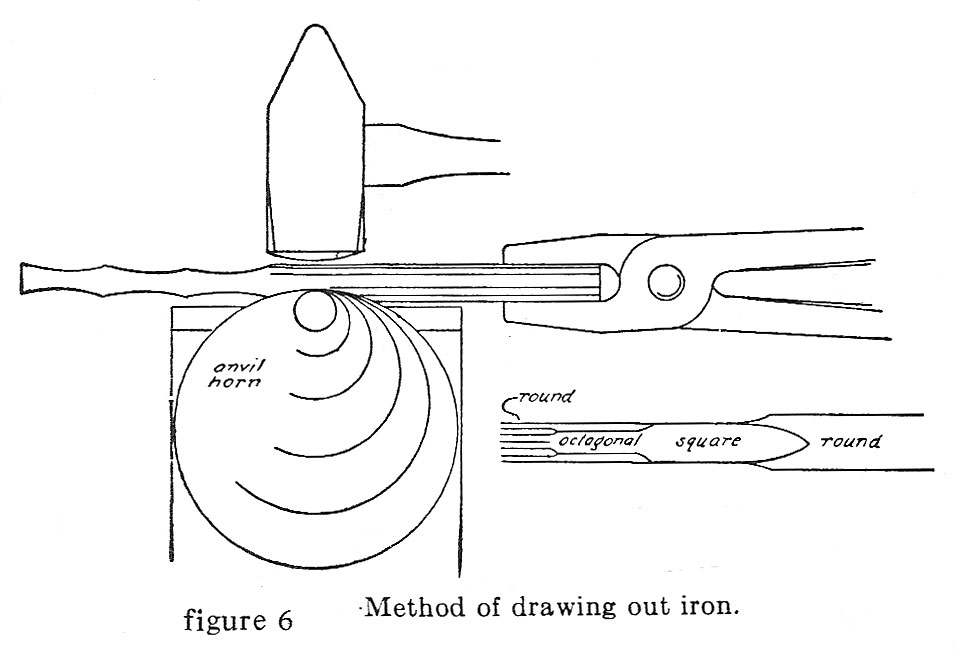

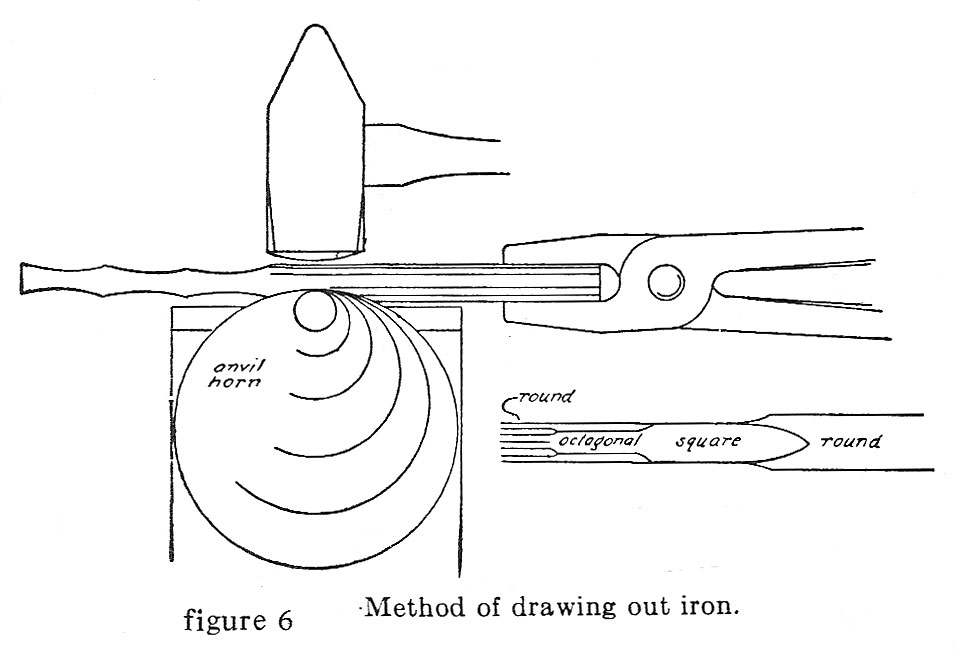

. Peens draw out steel at 90 degrees to the peen. The metal is heated at a temperature between to and the hammer is struck at the beak of the anvil. An even more extreme movement may be achieved by working the iron over the edge of the anvil but it will have to be hammered back smooth by rotating the red-hot iron under.

Keep the hammer bobbing in a straight-up-and-down motion and just turn the metal piece. Time and time again I have seen these hammers beat to heck with faces that are worn smooth from use. Its really that simple.

Hammer each blow with equal effort for uniform marks or textures. Lets see the difference. Oh yeah and KEEP IT HOT.

This has been shown in the figure. The harder cold steel will not be damaged by the hammer if the area being bent is hot enough. Make this shape as large as the first one but smaller in height.

Hammers are made out of a multitude of steel types but the most common include 4340 4140 and 1045-1060 steels. Forge anvil hammer ruler square. Just draw a thin rectangle on top of the handle to form the main part of the head.

Hold the hammer lightly in your palm and let it bounce off the metal in a fluid motion. How much crown should I give them. Features a weight forward balance like a dogs head hammer to give more precise control when drawing clips drawing out material and doing other precision or fine work.

The rounding hammer has a round face for drawing and a flat face for smoothing. Then to draw out your steel correctly you will want to hammer indents perpendicular to the direction you want to lengthen your steel. To learn more about the steels you can use to make your hammer and the conditions they require for proper welding.

Use that end to create little hills and valleys in the steel then use the flat end of your hammer to even it all out again. Fuller is also used for this purpose. First sketch the handle of your hammer by drawing a long and thin rectangle.

When getting into blacksmithing learning proper hammer strikes and heat levels for your metal and forge are good to know but one of the most important techniques to know when hammering your metal is Drawing Out which is a method that you use to make your metal thinner and longer or thinner and flatter. On top of this new shape add another rectangle. Vote in the commen.

If you hammer softly most of the time and harder once in awhile those harder blows will stand out. 1 chasing hammer Repouse ball pein planishing metal jewellers tools 25mm face 300 Ad by alfindingsltd Ad from shop alfindingsltd. The shorter tapered cross peen side keeps your strikes better centered when using the corner to draw a clean source.

Next add the head of your tool. Pound ram treadle hammer if that makes a difference. Im making some dies out of 2 square 4140 for my treadle hammer.

To shorten and thicken a piece of metal after heating it is called jumping or upsetting. To increase metals length is called Drawing out. Then once you have done that you flatten out the ridges or you rotate your stock.

Rotate workpiece 90 and repeat. 101610 855 PM. Youd be surprised at how quickly it can go if you use the appropriate sized billet keep the steel hot and know the right hammering techniques.

You can draw out steel faster with a round faced hammer than a flat faced hammer. Students will learn to draw out tapers of specified length and check their results for accuracy. Bar isnt bending- Striking on the far side of the.

There are also other tools such as fullersthe point is you have options. In blacksmithing jargon the term drawing out means to forge the stock longer and thinner. Intent is to use them to draw out Damascus billets.

This also introduces a nice randomness into the layers. Cernable hammer marksThe beginning of the taper should be a crisp line. Machined from 4140 and hand finished.

On top of this use the cross peindiagonal peinstraight pein end as well. Hydraulic press or power hammer. It is used for making channel V grooves to make inside corner of the job and for expanding metal sheets.

Drawing out steel on the forging press vs power hammer. This metal handled Estwing hammer is probably the most identifiable out of our test. Since the hammer face is slightly rounded and the horn of the anvil is rounded you will get more movement by drawing out on the horn than on the flat face of the anvil.

Unlike wood handled hammers these metal handled Estwing tools have the distinction of being nearly indestructible. A big part of getting better as a smith will be. In this video i played around on my home made power hammer and drew out a lot of steel.

It has been shown in the figure. If you dont already know learn how to draw steel by using the back of your hammer to create grooves and then hammering them out. Ive found this to be a pretty fast way to draw out.

You can use your anvils edge for drawing out metal if you know the technique for it. These kinds of steel have better toughness weldability and general suitability for hammers than their counterparts. What happens if I make them more or less crowned in terms of how they will move the steel.

5 out of 5. You can also draw out just as fast with a flat faced hammer by forging with a rounded surface under the steel by using the horn. Just buy whichever style piques your interest the most.

Hell you dont even need a peen on your hammer for drawing out metal. 24 of 12 square mild steel bar this is enough material to practice the exercise several times. Which one will win.

A cross pein hammer draws the work out in a linear fashion while a flat faced hammer spreads it in all directions. This is the most basic operation and one that almost every blacksmithing project will use.

Blacksmithing 6 The Basic Hammer Blows Youtube

Steel Hammer Drawing On Ruled Paper Stock Illustration Download Image Now Istock

Blacksmith Challenge An Introduction And Drawing Out Some Tapers Youtube

Blacksmithing Small Farmer S Journal

Drawing Out Steel Beginners Place Bladesmith S Forum Board

Blacksmithing 3 Drawing Out Metal Youtube

Blacksmith Doing The Drawing Out Challenge Youtube

How To Quickly Draw Out Steel With A Hand Hammer Youtube Metal Working Projects Blacksmithing Knives Metal Shop

0 comments

Post a Comment